TSC-Bearbeitung für Mazatrol Maschinen

Dynamisches Fräsen auf Mazak

Den Vorteil von trochoidalen Werkzeugbahnen in Mazatrol Programmen verwenden

Die Zusatzoption „Trochoidales Fräsen“ für MazaCAM CAD CAM erlaubt Ihnen dynamische Werkzeugbahnen zu erstellen und zusammen mit dem Mazatrol Programm auszugeben. Dynamisches, oder trochoidales Fräsen ermöglicht Ihnen schnelle Bearbeitungszeiten bei höheren Werkzeugstandzeiten.

Dynamisches oder Trochoidal fräsen- kurz TSC (Trochoidal Speed Cutting > auch Wirbel- oder Taumelfräsen genannt) erlaubt Ihnen eine Bearbeitungen mit höheren Schnittgeschwindigkeiten bei gesteigertem Vorschub. Mit diesen gesteigerten Schnittwerten kann über die zirkulare Werkzeugbahn, bei gerigem Seitenversatz (Ae) und hoher Schnitttiefe (Ap),die Schnittkraft und der Werkzeugverschleiss erheblich reduziert werden. Dadurch werden ebenfalls deutlich kürzere Bearbeitungszeiten sowie geringere Vibrationen an Maschine und Bauteil erreicht.

- Das Zusatzmodul zur Erzeugung dynamischer/trochoidaler Werkzeugbahnen erlaubt Ihnen diese moderne Bearbeitungsstrategie zu nutzen, ohne auf den Vorteil der Mazatrol Steuerung verzichten zu müssen.

- Dieses Modul generiert moderne, dynamische Werkzeugwege und ist als Add-On zu unserem normalen 2D CAD CAM System erhältlich.

- Trochoidale Werkzeugwege ermöglichen Ihnen die Verwendung höherer Schnittwerte, bei größerer Tiefenzustellung, und geringerem Verschleiss der Werkzeuge, sowie einer geringeren Spindellast. Über die radiale Werkzeugbahn bleibt das Werkzeug optimal und minimal im Eingriff.

- Diese Art der Bearbeitung wird von der herkömmlichen Mazatrol Programmierung nicht unterstützt. Wenn Sie aus unserem CAD CAM System heraus ein Mazatrol Programm generieren bleiben alle regulären Mazatrol Prozesse /Bohren, Taschen, Linie, etc.) erhalten. Die Trochoidalbearbeitung wird je nach Programmgröße als Konvent.-Einheit oder als EIA/ISO-Unterprogramm aufgerufen. Dadurch erhalten Sie den Vorteil der Mazatrol Oberfläche und der Mazak Werkzeugdaten ohne auf umständliche und unübersichtliche DIN/ISO-Programme ausweichen zu müssen.

Vorteile Trochoidales Fräsen für Mazak

- Auf allen Mazak Dreh.- und Fräs.- und Multitaskingmaschinen dynamisch fräsen

- Mazak Integrex, Variaxis, und VTC800 ohne Extrakosten enthalten

- Reduzierung der Programmier.- und Bearbeitungszeit

- Einfachste Bedienung mit geringem Schulungsaufwand

- Keine Zusatzkosten für PostProzessoren

- Automatische Einbettung des trochoidal Prozesses in das Mazatrol Programm

- Geringe Kosten für Wartung, Support, etc.

- Moderne Bearbeitungen auf älteren Mazak Maschinen verwenden

Features Trochoidales Fräsen für Mazak

- Add-On zu MazaCAM CAD CAM

- Erstellung trochoidaler Werkzeugbahnen am 2D oder 3D Model

- Dynamische High-Speed Bearbeitung für Konturen und Taschen

- Automatische Einbindung der Trochoidalbearbeitung in das Mazatrol Hauptprogramm als Konvent Einheit oder als EIA/ISO Unterprogramm.

- Indxiert dynamisch fräsen, für Integrex, Variaxis, und VTC800SR

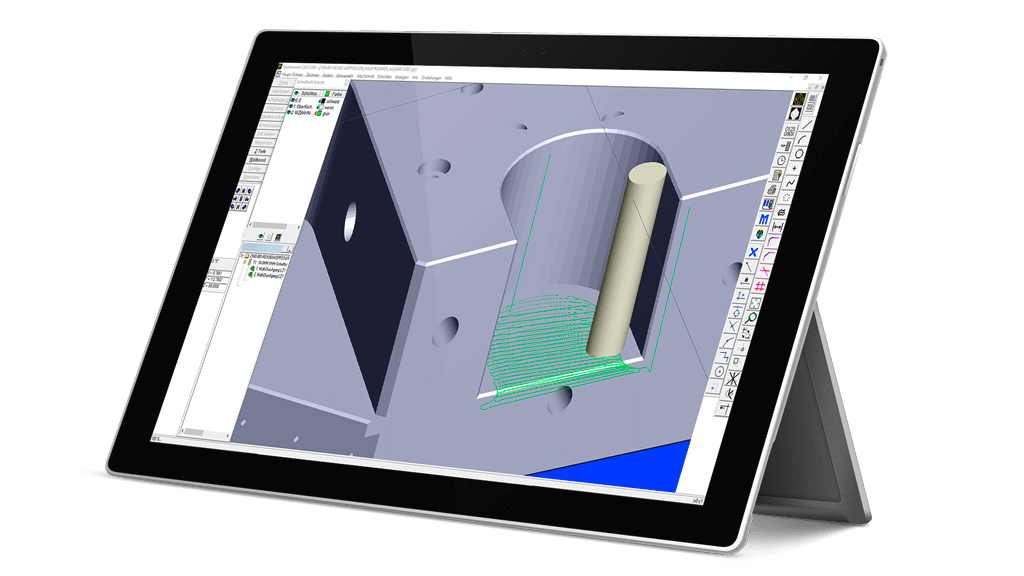

- Anzeige des Werkzeugweges und Kollisonskontrolle am Solid Modell

- Automtische Vorschubkontrolle für gleichbleibendes Spanvolumen und gleichbleibende Schnittkraft

- Auch für 3D Bearbeitung erhältlich

Nutzen Sie jetzt unsere Kontaktformulare um mehr Infos und ein persönliches MazaCAM Demo zu erhalten.